Hot Foil Printers: Introduction by Chinese Manufacturer & Supplier

Release time:

2025-10-10

Author:

Amydor

Source:

Original

As a professional Chinese manufacturer and supplier of hot foil printers, we offer 4 core models tailored to ribbon、 flat materials), 盒boxes, and labels applications—all featuring high precision, easy operation, and stable performance.

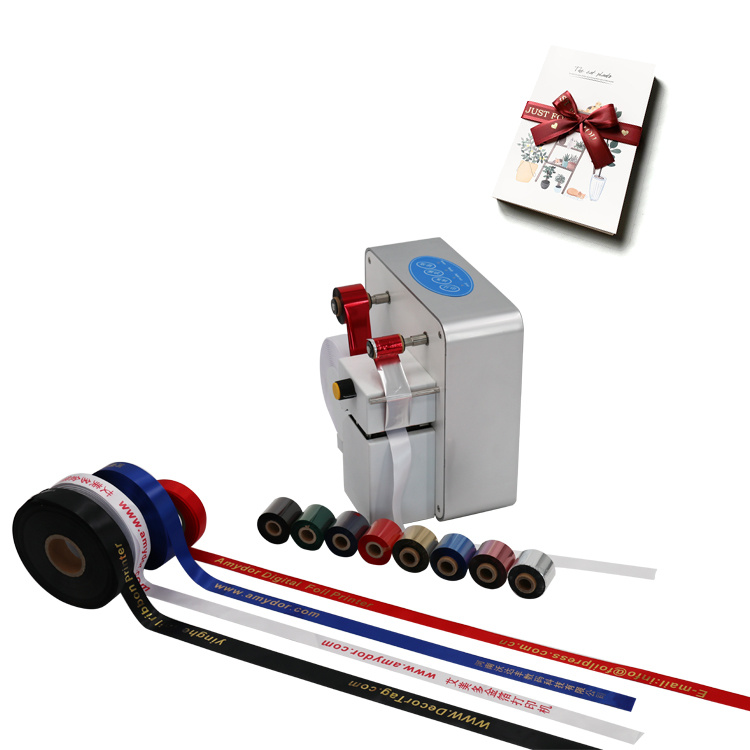

1. Ribbon Hot Foil Printer

Core Function: Specialized for continuous hot foil stamping on ribbons satin, organza, cotton.

Key Advantages: Supports 5-50mm ribbon width, 300 DPI precision for text/patterns.

User-Friendly: Auto ribbon feeding, adjustable speed, and pre-set temp for different ribbon materials.

2. Flat Material Hot Foil Printer

Core Function: Designed for flat substrates like paper, PVC, leather, and metal sheets.

Key Advantages: Max printing size A3, 300 DPI sharpness for business cards, book covers, and art prints.

Efficiency: Auto flat feeding, up to 400 pieces/hour, suitable for small-batch customization and medium-volume production.

3. Box Hot Foil Printer

Core Function: Optimized for hot foil stamping on various boxes (gift boxes, cosmetic boxes, hand-held boxes).

Key Advantages: Adapts to box surfaces (flat/slight curve), supports 35cm max material thickness, ideal for logo and pattern stamping.

Flexibility: Manual adjustment for different box sizes, no plate needed—cuts lead time for custom box orders.

4. Label Hot Foil Printer

Core Function: Dedicated to high-precision foil stamping on labels (wine labels, cosmetic labels, cable labels).

Key Advantages: 300 DPI for fine text/logos, compatible with label materials (paper, PVC, PET).

Practicality: Auto label feeding, durable foil adhesion, fits retail and industrial labeling needs.

Leave A Comment

* Note: Your email address will not be published. Required fields are marked

Recommend Blog